Add to Cart

Shenzhen OEM CNC Magnesium Precision Machining For Aerospace UAV Products

JYH Manufacturing Aerospace UAV Products Capabilities

Our facility has CNC machining centers, CNC lathes, CNC longitudinal lathes, slow-speed wire cutting machines and so on,

providing much manufacturing flexibility. Our engineers select the ideal equipment for an application based on the geometry, material,

and volume of the part being machined to provide customers with premium quality parts at the best possible price.

Application Range

Car engine accessory bracket, clutch housing, gearbox housing, instrument panel frame, steering wheel frame, seat frame, valve body mobile phone,Drone/camera.Magnesium alloy is very suitable for this kind of product because it is very light.

Available material

Magnesium is lightweight and has excellent castability and high specific strength, which gives it application in the automotive industry.

Magnesium has applications in producing engine blocks, gearboxes, clutch housings, wheels and engine cradles, and oil pans.

Magnesium’s natural properties, along with the benefits it provides those using it, make it an attractive option for CNC machining.

Lead time: <10 days

Tolerances: ±0.125mm

Max Part Size: 200 x 80 x 100 cm

| Material Type | Tensile Strength | Elongation | Yield Stress | Density | Maximum Temperature | Tensile Modulus |

| AZ91D | 230MPa | 3.0% | 150MPa | 1.81g/㎤ | 595℃ | 44.8GPa |

| AZ80A | 290MPa | 2.0~5.0% | 179MPa | 1.81g/㎤ | 595℃ | 45Gpa |

| AZ31B | 280MPa | 8% | 160MPa | 1.76g/㎤ | 595℃ | 46GPa |

| ZK61B | 330Mpa | 12% | 178MPa | 1.81g/㎤ | 630℃ | 47GPa |

| AZ61B | 280Mpa | 14% | 165Mpa | 1.81g/㎤ | 653℃ | 45GPa |

| AM60B | 221MPa | 4.0% | 131Mpa | 1.81g/㎤ | 428℃ | 44.8GPa |

PROPERTIES

The chief appeal of magnesium is its weight. Magnesium and its alloys are as light as plastic, but as tough as metal.

When alloyed, magnesium’s strength-to-weight ratio exceeds all other structural metals.

This gives the material a tensile strength on par with steel and aluminum, as well as a low density that’s helpful for

reducing weight — and, in turn, increasing fuel efficiency — in automobiles.

Magnesium is also very easy to machine compared to other metals. Sawing, punching, drilling, milling, turning, and

other processes are smoother when using magnesium, and machining the material requires a significantly lower cutting force and overall production time than other metals.

| Type | Tolerance |

| Linear dimension | +/- 0.015 mm |

| Hole diameters (not reamed) | +/- 0.015 mm |

| Shaft diameters | +/- 0.015 mm |

| Part size's limit | 850 * 650 *550 mm |

Surface Finishes For CNC Machined Magnesium Parts

►Sand or Bead Blasted

A process where abrasive materials are blasted onto the magnesium part's surface to create a matte or textured finish. It's useful for removing surface imperfections and preparing the part for other finishes.

►Anodized

An electrochemical process that forms a protective oxide layer on the magnesium surface. This layer enhances corrosion resistance, wear resistance, and provides a better adhesive surface for paints and primers.

►Chromate Conversion Coated

A chemical process that applies a chromate film onto the magnesium surface. This coating offers improved corrosion resistance, serves as a primer for subsequent coatings, and can provide electrical conductivity.

►Passivate

A chemical treatment that forms a protective oxide layer on the magnesium surface, enhancing its corrosion resistance.

►Powder Coated

A dry finishing process where a powdered paint is electrostatically applied and then cured under heat. It provides a durable, uniform, and attractive finish.

►Plating

Applying liquid paint to the magnesium part for aesthetic appeal and added protection against corrosion.

►Polished

A process that smoothens the magnesium surface to give it a shiny, mirror-like finish. It enhances the part's appearance and can also improve its resistance to corrosion

►Electroplating

A process where a thin layer of metal (like nickel or chrome) is deposited onto the magnesium part using an electrical current. It enhances the part's appearance, wear resistance, and corrosion resistance.

►Laser Marking

A non-contact process that uses a laser to mark or engrave the magnesium surface. It's ideal for adding logos, barcodes, or other identifiers.

Quality Inspection

we have a coordinate measuring machine, salt spray testing machines, profile projectors and other precision

measuring devices, etc.

direct comparison to the dimensions that are taken from the physical part.

GB/T 16857.2-2006 (ISO10360-2:2001) standards. All components and sub-assemblies are 100% inspected,

identified with a logo if required and a final inspection is generated pertaining to all the critical dimensions.

Our shipping method

Our payment method

Our workshop

FAQ:

| 1-Is magnesium hard to machine?

|

| 2-Can you CNC magnesium?

|

| 3-How many machines do you have?

|

| 4-How do I get a quote?

|

| 5-What types of files do you accept?

|

| 6-Do you provide First Article of Inspection (FAI) Service?

|

| 7-What is payment term does your company can be acceptable?

|

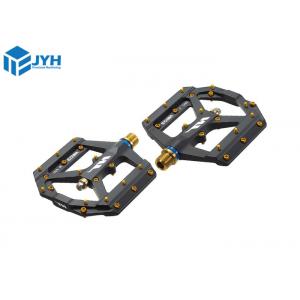

Magnesium Sample Pictures for your reference:

JYH technology, Your Professional CNC Machining Magnesium Alloy Services Partner!